what are the three basic areas of a machine that require safeguarding

Dangerous moving parts in three basic areas require safeguarding. The safeguard must prevent hands arms and any other part of a operators.

Machine Guarding Environmental Health Safety

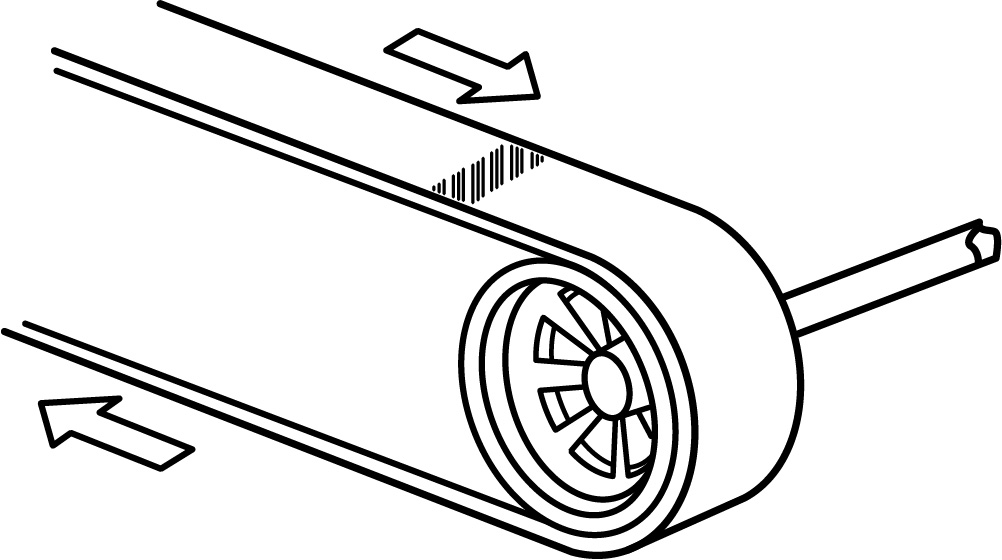

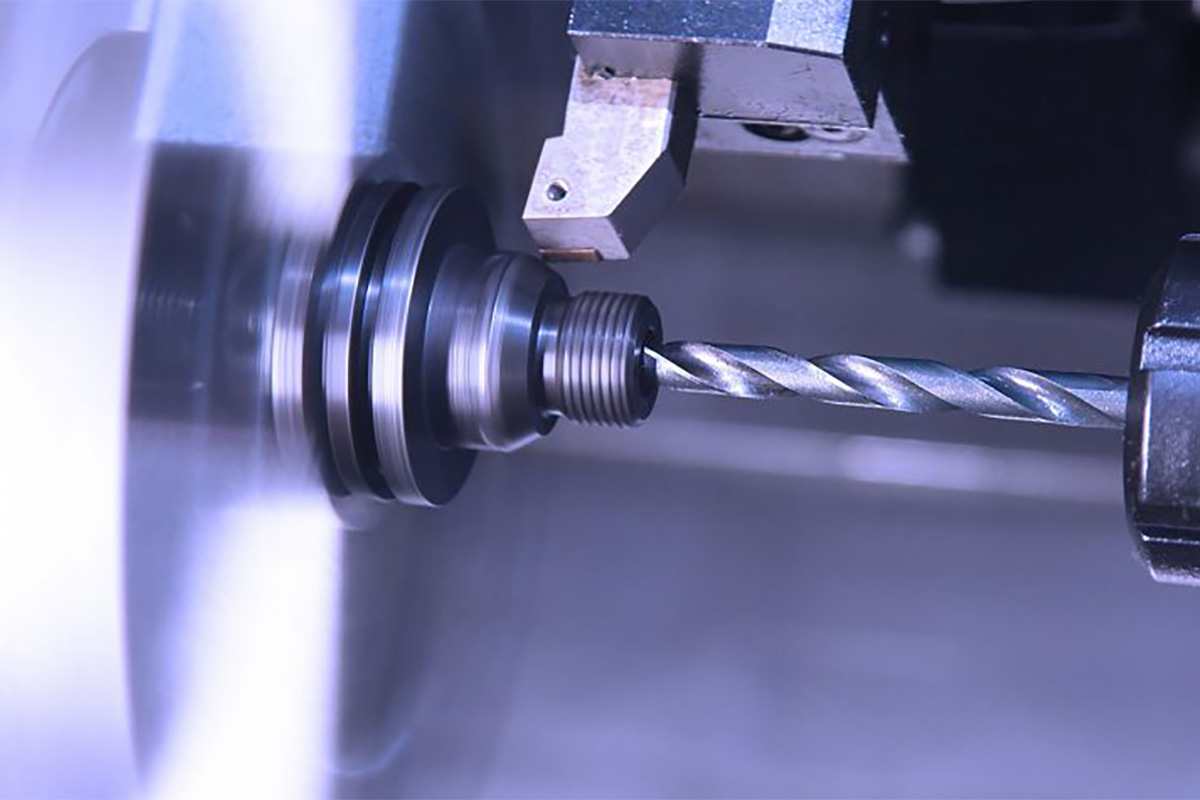

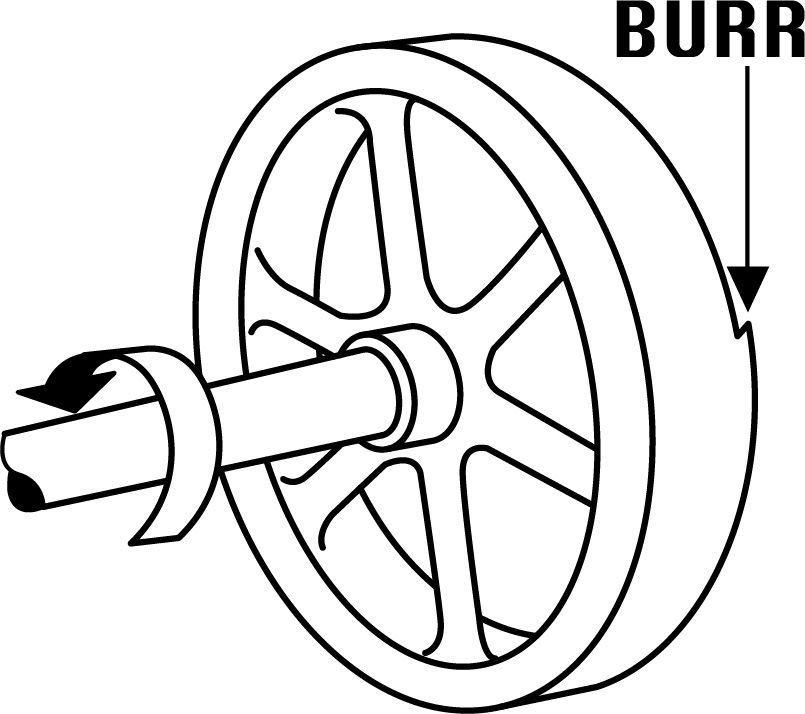

Even smooth slowly rotating shafts can grip clothing and.

. Friday May 6 2022. Dangerous moving parts in these basic areas require safeguarding. Dangerous moving parts in three basic areas require safeguarding.

Safeguards must meet these minimum general requirements. There are three basic types of motion. Point of operation 2.

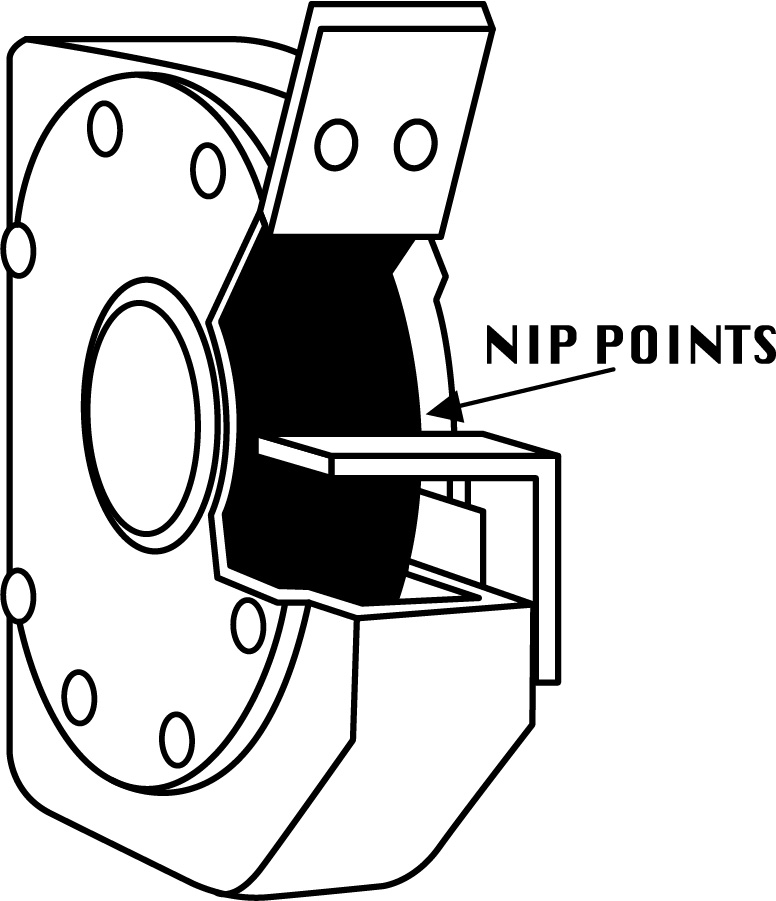

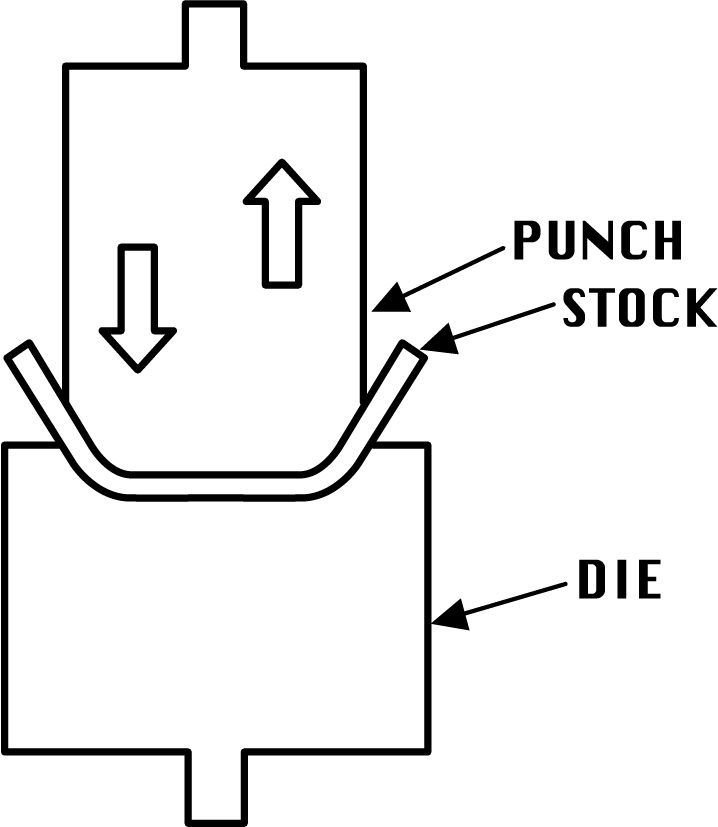

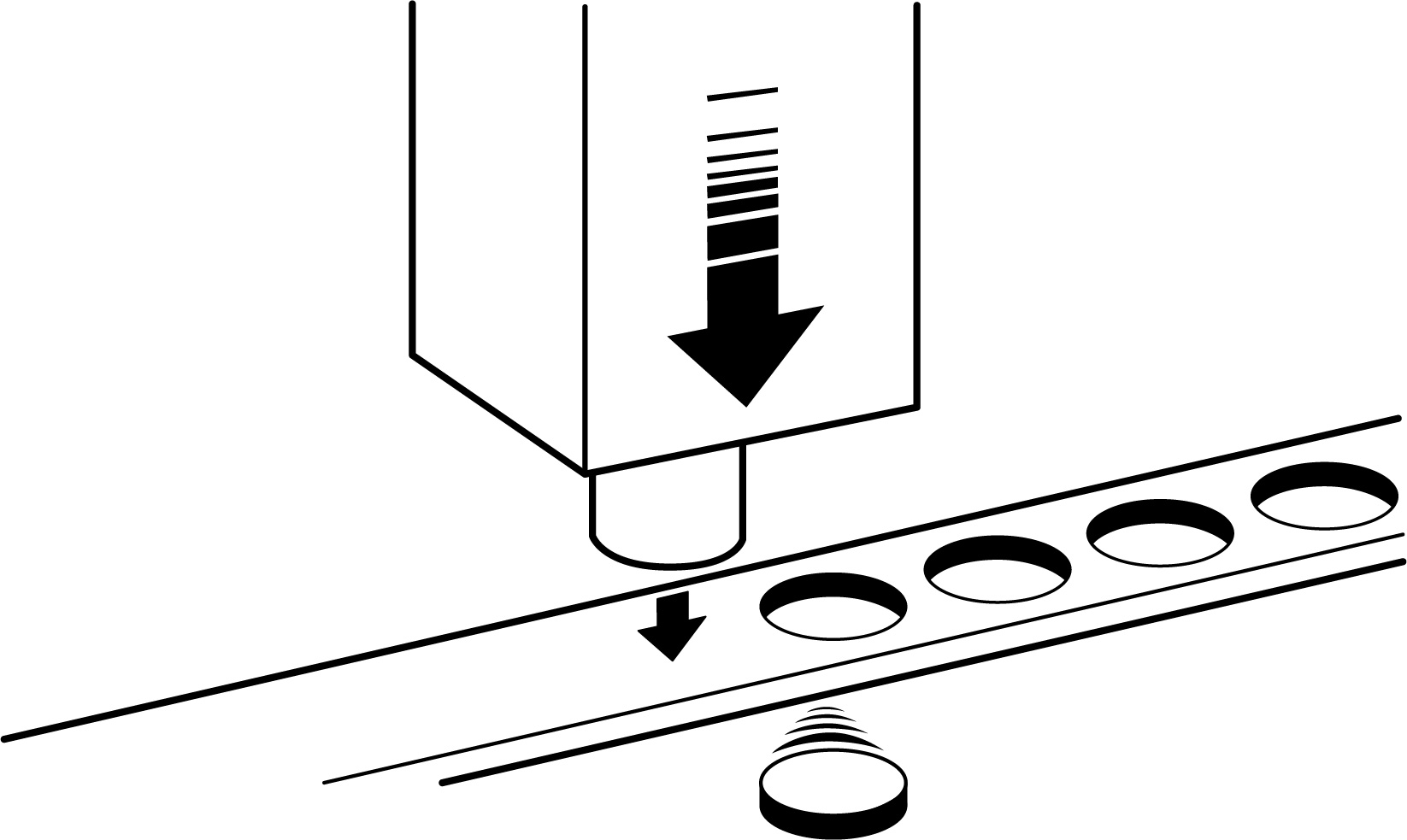

Point of Operation Power Transmission Apparatus Other Moving Parts Question 2. That point where work is performed on the material such as cutting shaping boring or forming of. What are the three basic areas of a machine that require safeguarding.

That point where work is performed on the material such as cutting shaping boring or forming of. Describe the basic hazards involving machinery including point of operation and power transmission devices. The point of operation.

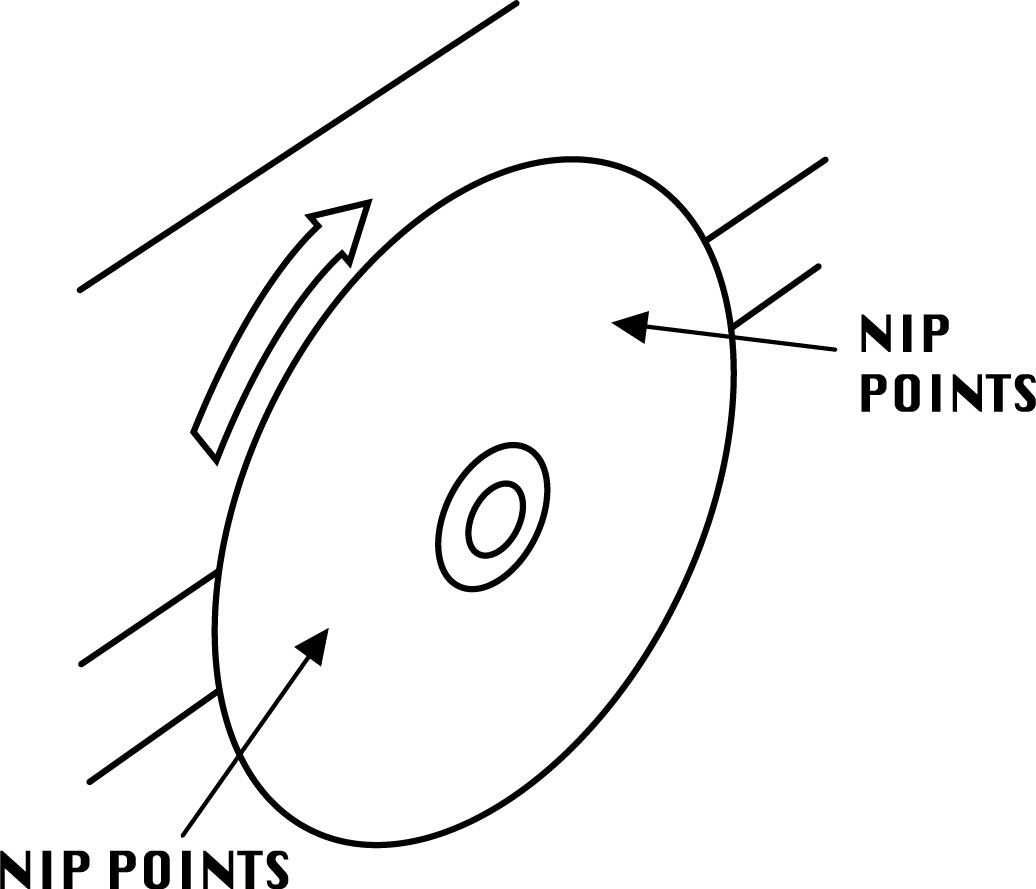

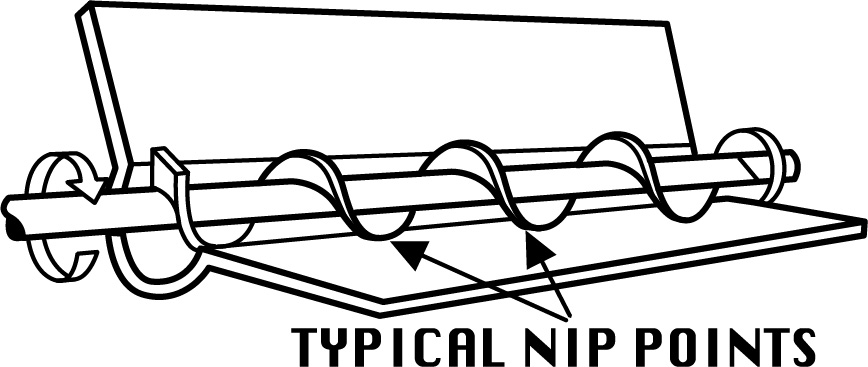

The point of operation the power transmission device and the operating controls. Rotating reciprocating and transverse. In running nip points 3.

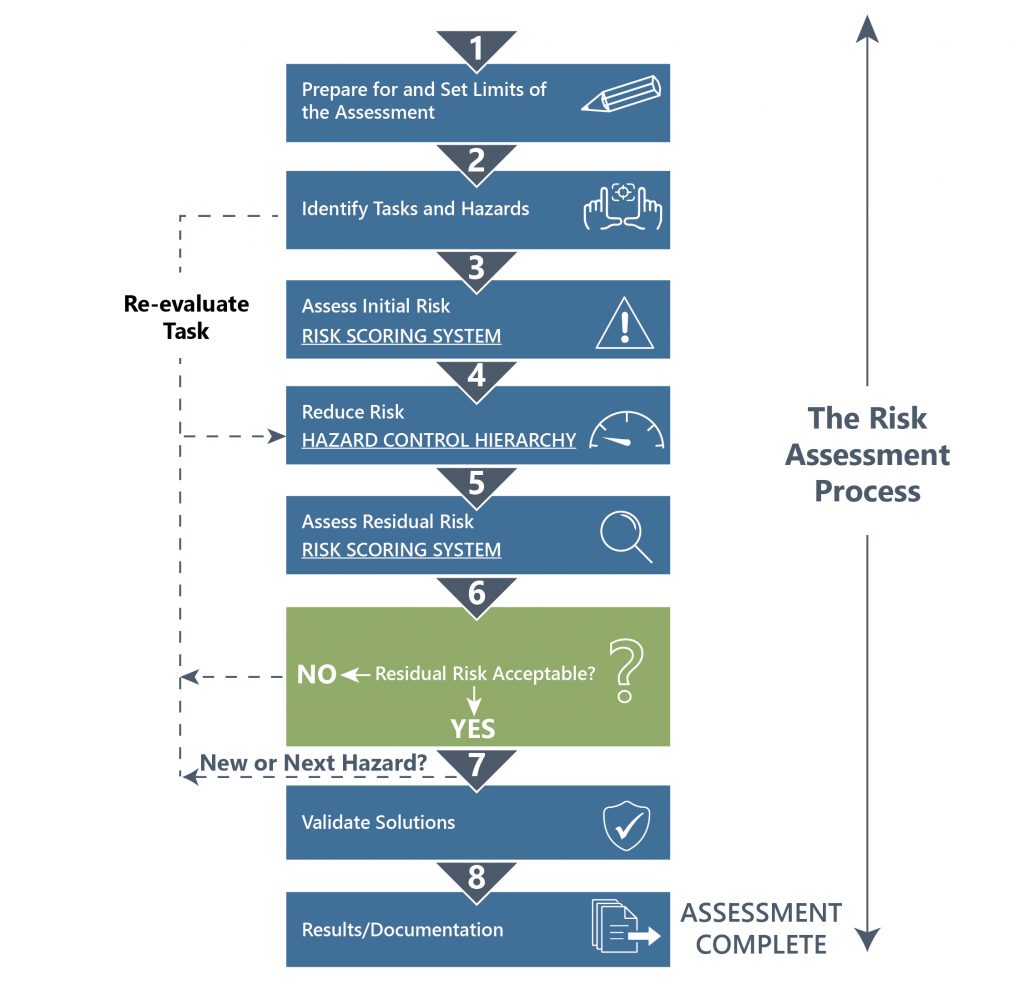

Despite all machines having the same. Introduce control measures through effective machine guarding. Dangerous moving parts in three basic areas require safeguarding.

All components of the mechanical system which transmit energy to the. Dangerous moving parts in three basic areas require safeguarding. What are the three basic areas of a machine that require safeguarding.

Dangerous moving parts in three basic areas require safeguarding. Mechanical hazards typically involve dangerous moving parts in the following three basic areas. Machine safeguards must meet these minimum general requirements.

The point of operation. The safeguard must prevent hands arms or any other part of a workers body from contacting. Rotating motion can be dangerous.

That point where work is performed on the material such as cutting shaping boring or forming of. The point of operation. All machines consist of three fundamental areas.

The point of operation. That point where work is performed on the material such as cutting shaping boring or forming of.

Machine Safeguarding 101 Rockford Systems Llc

Machine Guarding Environmental Health Safety

Osha Requirements Machine Guarding Grainger Knowhow

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Osha Requirements Machine Guarding Grainger Knowhow

Templates Machine Safeguarding Program

Machine Guarding Different Types Of Machine Guards

Osha Requirements Machine Guarding Grainger Knowhow

Machine Guarding Different Types Of Machine Guards

Osha Requirements Machine Guarding Grainger Knowhow

Welcome Crushed Hands And Arms Severed Fingers Blindness The List Of Possible Machinery Related Injuries Is As Long As It Is Horrifying There Seem Ppt Download

Osha Requirements Machine Guarding Grainger Knowhow

Osha Requirements Machine Guarding Grainger Knowhow

Chapter 1 Basics Of Machine Safeguarding

Chapter 1 Basics Of Machine Safeguarding

Osha Requirements Machine Guarding Grainger Knowhow

Osha Requirements Machine Guarding Grainger Knowhow

The Guarded Truth Answers To Machine Guarding Compliance Faqs Ensafe